In the modern world of custom printing and personalization, transfer stickers have become an essential tool for businesses, hobbyists, and creative professionals. Among them, DTF transfer stickers are gaining significant popularity due to their versatility, vibrant colors, and durability. Whether you are looking for UV DTF transfers or standard DTF transfers, these products allow for high-quality, long-lasting designs on a wide range of materials.

This comprehensive guide explores everything you need to know about transfer stickers, including types, applications, advantages, and why DTF transfers have become the go-to solution for custom printing.

1. What Are Transfer Stickers?

Transfer stickers are a type of sticker that allows you to transfer a design or graphic onto another surface, such as fabric, metal, plastic, or wood. Unlike traditional stickers, transfer stickers can adhere smoothly to surfaces without visible borders or edges.

DTF transfer stickers (Direct-to-Film) take this a step further. They allow full-color printing directly onto a film, which can then be heat-transferred onto a target surface. The process ensures precision, durability, and vibrant color reproduction.

With the integration of UV DTF transfers, these stickers are now resistant to fading, scratching, and external environmental factors, making them perfect for both indoor and outdoor applications.

2. Types of DTF Transfers and Stickers

There are several types of DTF transfers and DTF stickers, each catering to different needs:

2.1 Standard DTF Transfer Stickers

-

Printed on specialized transfer film

-

Heat-applied to fabrics or other surfaces

-

Ideal for custom t-shirts, apparel, and accessories

2.2 UV DTF Transfers

-

Coated with UV-resistant ink or laminate

-

Enhanced durability under sunlight and harsh conditions

-

Perfect for outdoor signage, promotional items, and high-wear products

2.3 DTF Stickers for Hard Surfaces

-

Suitable for metal, plastic, and wood

-

Can be applied to mugs, bottles, phone cases, and packaging

-

Flexible and resistant to peeling or cracking

3. Advantages of DTF Transfer Stickers

DTF transfer stickers and UV DTF stickers provide a range of benefits that make them superior to other transfer methods like screen printing or vinyl transfers:

3.1 Vibrant Color Reproduction

DTF transfers allow full-color printing with detailed gradients, shadows, and highlights. UV coatings enhance color vibrancy and prevent fading.

3.2 Durability and Longevity

-

UV DTF transfers are highly resistant to UV light, scratches, and washing.

-

Maintains quality for years without cracking or peeling.

3.3 Versatility

DTF transfer stickers can be applied to nearly any surface, from textiles to metals, plastics, glass, and wood.

3.4 Ease of Application

-

Peel-and-stick or heat-press methods are simple and require minimal skill.

-

Ideal for small businesses, hobbyists, or large-scale production.

3.5 Cost-Effective

Compared to traditional printing, DTF transfers reduce setup costs and allow low-volume customization without sacrificing quality.

4. Materials and Manufacturing Process

Understanding the materials used in DTF transfer stickers is key to appreciating their quality and functionality.

4.1 Transfer Film

-

High-quality PET film provides a smooth surface for printing.

-

Ensures the design adheres correctly and evenly.

4.2 Adhesive Layer

-

Heat-activated adhesive allows the design to bond strongly to various surfaces.

-

UV-resistant adhesives prevent peeling in harsh conditions.

4.3 Ink Technology

-

DTF inks are pigment-based for vivid colors.

-

UV DTF ink adds durability and weather resistance, ideal for outdoor applications.

4.4 Powder Coating

-

Special adhesive powder ensures the printed image adheres perfectly during the heat transfer process.

-

Critical for long-lasting DTF transfer stickers.

5. Applications of DTF Transfer Stickers

DTF transfer stickers are widely used across industries due to their versatility and durability.

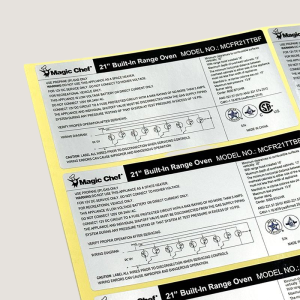

5.1 Apparel Customization

-

T-shirts, hoodies, hats, and sportswear

-

UV DTF transfers ensure designs remain vibrant after repeated washing

5.2 Promotional Products

-

Water bottles, mugs, phone cases, and notebooks

-

Durable UV DTF stickers maintain brand visibility

5.3 Packaging and Branding

-

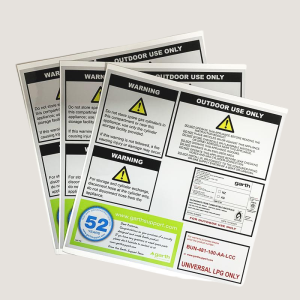

Custom labels, packaging designs, and product stickers

-

Enhance brand recognition and appeal

5.4 Industrial Uses

-

Signage, equipment labeling, and safety markings

-

Resistant to environmental factors thanks to UV DTF transfers

6. How to Apply DTF Transfer Stickers

Applying DTF transfer stickers is straightforward, whether you are using UV DTF stickers or standard ones. Follow these steps for best results:

-

Prepare the Surface: Ensure the surface is clean, dry, and free of dust or oil.

-

Position the Sticker: Align the transfer sticker or DTF transfer film precisely on the surface.

-

Apply Heat (if required): For heat-transfer stickers, use a heat press or iron at recommended temperature.

-

Peel the Film: Carefully peel the transfer film while the adhesive is still warm.

-

Cure and Finish: Allow the sticker to cool and bond fully for long-lasting results.

7. Why Choose UV DTF Stickers?

For businesses and creative professionals looking for the ultimate combination of quality and durability, UV DTF transfers are the perfect solution. Their UV resistance prevents fading, while their flexibility ensures smooth application on curved or textured surfaces.

Brands that use UV DTF stickers benefit from:

-

Long-term visual appeal

-

Resistance to scratches and environmental wear

-

Premium look and feel for high-end products

8. Tips for Choosing the Right DTF Transfers

When selecting DTF transfers or DTF transfer stickers, consider the following factors:

-

Material Compatibility: Ensure the transfer works with fabric, plastic, or metal surfaces.

-

UV Protection Needs: Outdoor products benefit from UV DTF transfers.

-

Color Vibrancy: Check ink quality and printing precision.

-

Durability Requirements: For high-wear items, UV coatings or special adhesives are essential.

-

Custom Design Options: Look for suppliers offering customizable sizes, shapes, and finishes.

9. Common Misconceptions About DTF Transfers

-

Misconception 1: DTF transfers are only for fabric.

Fact: They can be applied to plastics, metals, glass, and wood. -

Misconception 2: UV DTF stickers are expensive.

Fact: While slightly higher cost, their durability and color retention provide long-term savings. -

Misconception 3: DTF transfers are hard to use.

Fact: Simple application methods make them suitable for small businesses and hobbyists.

10. Conclusion: The Ultimate Solution for Custom Stickers

Whether you are a small business owner, an artist, or a large-scale manufacturer, DTF transfer stickers and UV DTF transfers offer unmatched versatility, durability, and visual impact. By adopting DTF transfers, you gain access to a wide range of applications, vibrant colors, and reliable performance across multiple surfaces.

Investing in high-quality DTF transfer stickers ensures that your brand, designs, and custom creations look professional, last longer, and leave a lasting impression on customers.

Make the switch to DTF transfers today and experience the future of high-quality, customizable transfer stickers.